Quality Material, Parts & Customer Service

Quality Material, Parts & Customer Service Crack Sealing Materials & Equipment

Crack Sealing Materials & Equipment High Performance Cold Mixes

High Performance Cold Mixes HDPE Drainage Pipe & Fittings

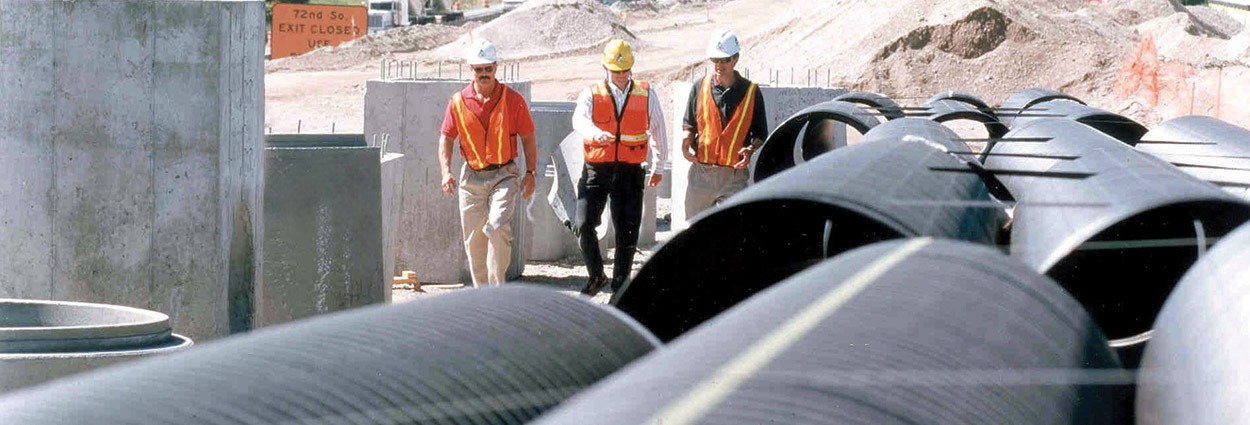

HDPE Drainage Pipe & Fittings Pavement Repair Materials

Pavement Repair Materials Concrete Repair Materials

Concrete Repair Materials Asphalt Repair Materials

Asphalt Repair Materials Pavement Adhesion Promoters

Pavement Adhesion Promoters Application Equipment.

Application Equipment. Waterproofing Products

Waterproofing Products

Denver Industrial Sales and Service Company Inc. (DISSCO) is a manufacturer and supplier of quality materials and application equipment providing parts, sales, service and rentals with superior customer service to the Rocky Mountain Region since 1949.

DISSCO is a second-generation family owned and operated organization where our number one goal is customer satisfaction. We appreciate you taking the time to check us out and if you cannot find the information you need, please feel free to call us at our toll free number at 877.935.2485.