ULTRA BLOCK® is a pre-engineered, patented textile fiberglass with fiberglass matt facing, containing approximately 30% by weight unexpanded vermiculite.

ULTRA BLOCK® is primarily used in fire rated construction joints.

Specific Uses:

Structural fire proofing was established in 1917 when the ASTM committee established ASTM E19. Today, E19 has evolved to ASTM E119 and ANSI/UL2079. The International Building Code requires documentation that building assemblies, components and structural elements be fire tested in accordance with test procedures set forth in ASTM E119 and ANSI/UL2079. All of the ULTRA BLOCK® UL design systems comply with The International Building Code.

When architects design a structure, they will design and build in mechanical, expansion/construction joints. The joints are to compensate for the ongoing everyday expansion and contraction that a building must withstand. When the code dictates that these structures be fire rated, the expansion joint system installed must be fire rated equal to adjacent structure. The expansion joint system must be capable of taking the opening and closing of joint design and remaining in place to perform its fire rated design function if and when it is ever needed.

Limitations:

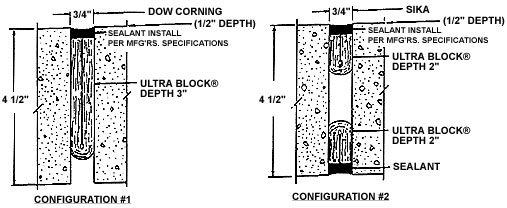

All ULTRA BLOCK® Expansion Joint systems are a minimum 2-component design. The depth of the ULTRA BLOCK® controls the heat sink or temperature rise from the hot face to cold side of the structure. The addition of an elastomeric sealant, nominal 1/2" thick, to either one or both sides contains the smoke, the toxic fumes and the unburned gases.

Every major sealant manufacturer in the United States has tested one or more of their sealants in a UL classified ULTRA BLOCK® system.

|

|

ULTRA BLOCK® will be installed under standard design compression. "C&D" Clean & Dry joint is required for sealant to gain full adhesion to sides of joint.

Composition and Materials:

All ULTRA BLOCK® systems are manufactured per project requirements. For single layer installation, the following dimensions "A" and "B" can vary.

- "A" folded in half becomes depth. Depth dictates Fire Rating.

- "A" 6 in. folded and installed - 3 in. equals 2 hour Fire Rating.

- "A" 8 in. folded and installed - 4 in. equals 3 hour Fire Rating.

- "A" 12 in. folded and installed - 6 in. equals 4 hour Fire Rating.

Use following table thickness selection:

| Joint Width | Use | Roll Length |

|---|---|---|

| 1/2" | 3/8"thk. | 70 LF |

| 3/4" | 1/2"thk | 60 LF |

| 1" | 3/4"thk | 40 LF |

| 1 1/2" | 1"thk | 30 LF |

Joint widths of 2" or wider require our multi-layer designs. Contractor must tell us joint width, hourly fire rating and configuration required.

Technical Data

Under the guidance and direction of Underwriters Laboratories, Northbrook, Illinois, Backer Rod Mfg. Inc. established our Master File R13729. All of our testing was to the FULL SCALE, 180 sq. ft. pallet surface area and each joint tested was 12 ft. long. Our testing did include the hose stream portion. The test standard was ANSI/UL2079, ASTM E119, UL 263, NFPA 251. The full scale testing earned us classifications by UL in all horizontal and all vertical joints, plus compliance with The International Building Code. Many of these are multi-listings which include Floor to Floor, Floor to Wall, Wall to Wall and Head of Wall designs.

ULTRA BLOCK® systems allow the mechanical expansion/construction joint to function and fulfill the purpose it was designed for, " MOVEMENT."

Structural testing of ULTRA BLOCK® designs was performed by Hauser Research, Boulder, Colorado. Our systems testing was performed on a +/-50% movement for 28,775 openings and closings. On a once a day expansion and contraction, that equals 78 years or service. The standard for movement testing is ASTM E1399.

Seismic testing of ULTRA BLOCK® designs was performed by the University of California, San Diego, California. The seismic "Earthquake" test was a project name "TCCMAR" sponsored by the United States and Japan. ULTRA BLOCK® performed so well in their 2-story structure, that it was named as the single source for use in their 2nd test, a 5-story structure.

All ULTRA BLOCK® systems are covered with a nominal 1/2" depth elastomeric sealant (see list of manufacturers). System designs can range from 1-hour, 2-hour, 3-hour, or 4-hour fire ratings and joint width from 1/2" up to 7" wide. We ask that you verify that your sealant selection complies with our system design.

Applicable Standards:

- IBC – International Building Code

- ANSI/UL2079 – UL Standard for Safety Fire Tests for Fire Resistance of Building Joint Systems

- ASTM E 119 - Method for Fire Tests of Building Construction and Materials

- ASTM E 814 - Methods for Fire Tests of Through-Penetration Fire Steps

- ASTM E 84 - Test Method for Surface Burning Characteristics of Building Materials

- ASTM E 136 - Test Method for Behavior of Materials in a Vertical Tube Furnace at 750ºC

- ASTM E 90 - Test Method for Laboratory Measurement of Air-borne-Sound Transmission Loss of Building Partitions

- NFPA 251 - Fire Test of Building Construction Materials

- NFPA 255 - Burning Character of Building Materials

- ASTM E 1399 - Test Method of Cyclic Movement and measuring the Minimum and Maximum joint Widths of Architectural Joint System

- ASTM C 719 - Test Method for Adhesion and Cohesion of Elastomeric Joint Sealants Under Cyclic movement.

- ASTM C 920 - Specification for Elastomeric Joint Sealants

- UL 263-92 - UL Standard for Safety Fire Tests of Building Construction and Materials

- UL 2079 - UL Standard for Safety Tests for Fire Resistance of Building Joint Systems

- UL 1479 - UL Standard for Safety Fire Test of Through-Penetration Firestops

- UL 723 - UL Standard for Safety Test for Surface Burning Characteristics of Building Materials

Physical Properties:

ULTRA BLOCK® is a continuous filament textile glass fiber and may cause skin and eye irritation. When handling and/or applying, wear long sleeves, gloves and cap. Wear eye protection (goggles, safety glasses). MSDS verifies that ULTRA BLOCK® is : not listed, not regulated, and not classified as a carcinogen. That applies to both as installed and removal should a fire occur.

Content provided by Backer Rod Mfg. Inc.

Product Pages

Product Documents

[emaillocker id=1159]

Denver Foam®

- Brochure

- Technical Data Sheet

- Safety Data Sheet

Titan Foam®

- Brochure

- Technical Data Sheet

- Safety Data Sheet

Mile High Foam®

- Brochure

- Technical Data Sheet

- Safety Data Sheet

Mile High Foam XL™

- Brochure

- Technical Data Sheet

- Safety Data Sheet

Ultra Block®

- Brochure

- Technical Data Sheet

- Safety Data Sheet

[/emaillocker]