UPM® Cold Mix Performance Evaluation for Asphalt Pothole Repair

By: The Streets & Roads Division in Lexington, KY, directed by Sam Williams; Program support provided by Steve Wallace and Don Koehler of Unique® Paving Materials.

Introduction

The city of Lexington, Kentucky undertook a performance evaluation of cold mix pothole repair materials to determine the long-term best product for use on their many city streets. UNIQUE® Paving Material’s High-Performance Cold Mix was the winning product – reducing both the number of potholes that had to be repaired repeatedly and also the total number of potholes that developed – saving the city tens of thousands of dollars in labor, equipment and material costs.

In July 2011, the Lexington City News posted an editorial titled, “Patching Potholes Is Routine Work for Streets and Roads Crew.” The article pointed out that potholes are a fact of life. Indeed, sometimes it seems that potholes are simply everywhere. While this is especially true in the spring, the truth is that potholes on roads and streets are a year-round problem.

In July 2011, the Lexington City News posted an editorial titled, “Patching Potholes Is Routine Work for Streets and Roads Crew.” The article pointed out that potholes are a fact of life. Indeed, sometimes it seems that potholes are simply everywhere. While this is especially true in the spring, the truth is that potholes on roads and streets are a year-round problem.

Potholes are often created by the freeze-then-thaw cycle that Lexington experiences in winter as well as by damage caused by snow removal plowing.

“Sometimes, we get multiple work order requests for the same location,” explained Keith Martin, Street Department Supervisor. “If it gets to the point where we have to repair the same place multiple times, then we do an asphalt repair – we take out a section of the road and replace it.”

Striving to improve the overall handling process for potholes, Streets and Roads initiated a cold mix evaluation program. The purpose was to identify possible advantages using alternative pothole repair materials. Multiple parameters were considered in determining which candidate materials would be compared. The four parameters decided upon were:

- Survivability – the time materials stay in the repair

- Workability – ease-of-use during installation

- Total cost – initial, installation and re-repairs

- Availability in the Lexington area in bulk and bag quantities

The higher cost of the UPM® Permanent Pavement & Pothole Repair Material was initially a detriment when considering UPM’s premium cold mix product; however, if the labor and equipment commitment to street repair could be reduced through elimination of redundant repairs, the overall net gain would be substantial and far greater than the increased cost of material. The net result would be increased-resources availability for the city.

This line of thought is echoed in the Strategic Highway Research Program report:SHRP-H-353, Innovative Materials, by Thomas P. Wilson:

“Utilize the best materials available to reduce re-patching. The cost of patching the same potholes over and over because of poor-quality material quickly offsets the savings from purchasing a less expensive cold mix. In most cases, the poorer performance associated with inexpensive cold mixes will result in greater overall costs for patching because of increased costs for labor, equipment, traffic control, and user delay.”

Reviewing multiple commercial cold mixes, three products claiming superior performance were selected:

- UPM® High Performance Cold Mix

- Mago bulk cold mix

- QPR bulk cold mix

Field trials commenced in December 2011 and will continue for at least a year. Throughout the trial, preliminary reports will be issued. Multiple installations of both pothole and utility cuts will be photographed and rated.

Findings from the field trial will be incorporated into performance specifications used to select the best-in-class cold mix products for the City of Lexington.

This report summarizes the first five (5) months from January through May 2012.

Early in the program it was determined that the UPM® Cold Mix was superior to other candidate materials based on workability and survivability. Due to the observed performance differences and limited resources, it was decided to focus on the UPM® material.

Overall the UPM® material is outperforming previously used cold mix materials and candidate materials initially included in the evaluation, based on survivability and overall lower costs. The greater overall value of this material was quickly obvious through elimination of frequent re-repairs.

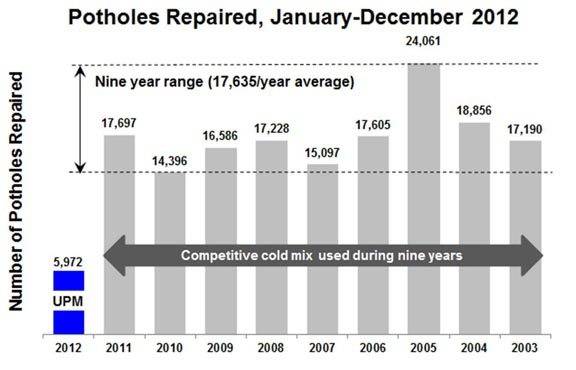

The following summary graph highlights the number of potholes recorded for the nine-year period from 2003-2011 (Jan-May), with an average of 10,262 per year. Starting in 2012 with the use of UPM’s Cold Mix Asphalt product, the number of recorded potholes decreased to 3,753 – a reduction of 63% – significantly below the previous nine year range and more than a 50% reduction in the number of potholes generated in Lexington.

Reference data provided by the City of Lexington Division of Streets and Roads.

The city’s centralized service and information contact center, LexCall, handles thousands of calls each winter from citizens reporting potholes. The Division of Streets and Roads is extremely aggressive and proactive in monitoring the city’s 2,124 lane miles its responsible for repairing and maintaining. This combination of documenting and reporting allows the city to maintain accurate records of repairs and costs attributed to them each year.

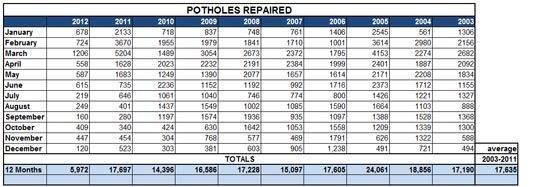

During the months of January to March 2011, the City of Lexington spent $352,224.00 repairing potholes. This is attributed to 11,007 potholes documented during this time period. Potholes were counted independent of being newly formed or a re-repairs. It is common to re-repair potholes – repair frequency is typically related to repair material quality.

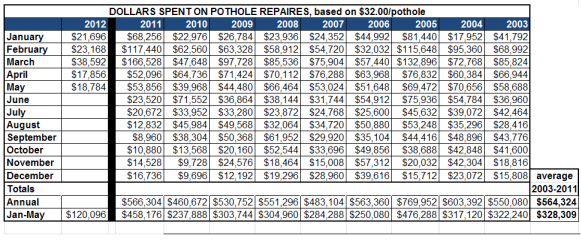

It was determined in a fiscal review of costs attributed to pothole repairs in 2011 that the cost to repair an average-size pothole was $32.00. For comparison, the $32.00 per pothole will be used to compare pothole repair costs.

The nine (9) year cost average from 2003-2009 for January through May was $328,309.00, repairing an average of 10,260 documented potholes.

This year, during the critical three-month period when most potholes are discovered and repaired (January-May), the city repaired 3,753 potholes – spending $120,096.00, significantly less than the nine-year average. This represents a $208,213.00 savings or a 37% annual savings for the city.

The primary contributor to the reduction in potholes in Lexington is the cold mix material from UPM®that goes in the hole once and stays there.

The absence of multiple re-repairs has resulted in the city saving two-thirds of their average budget for the first three months of the program. Increased savings are expected in the upcoming years as well.

In addition to these remarkable savings, the city reports that this is the first time in 9 years they have not had a claim for vehicle damage or injury caused by a pothole on any of the 2,124 lane miles within the city’s jurisdiction.

General Observations by Program Participants

Pothole count is 63% lower using the UPM® material relative to other cold mix materials. Controlled performance evaluations like that conducted by Lexington are the best method to determine the value using a premium cold mix. The process is difficult and can be time-consuming; however, the benefits in developing the correct pothole repair strategy are significant.

Director Sam Williams reported that in spite of the warmer temperatures, the city still experienced the freeze-thaw cycles normally expected during the winter months and attributes the cost savings to a high-performance pothole repair material that works.

In addition to the pothole count metrics maintained by the city, maintenance crews were requested to comment on overall handling and performance of the candidate cold mix products. As crews patch potholes it is difficult to record details of every installation as each is slightly different due to the severity of repair and quality of surrounding pavement. Completed repairs not requiring follow-up re-repair quickly drop from the maintenance schedule. This creates the opportunity to focus on newly formed potholes or other maintenance projects. After the five-month winter evaluation all crews agreed the UPM® material was superior to other cold mixes used through the previous nine years.

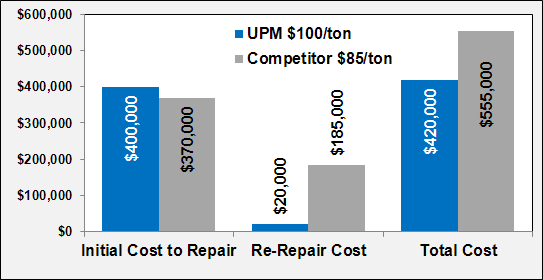

Now more than ever, Federal, State and local governments recognize the importance of spending their limited budgets on a product that works. And, while they understand they may pay a little more upfront for a premium product, both the cost savings and fiscal responsibilities have provided enormous dividends for them and their departments in the eyes of the administration and the tax payers. The total cost including pothole repair and re-repair should be considered in the cold mix selection process to maximize value to the city. As a result, a lower-cost product may save initial dollars; however, it is the total cost over the complete repair cycle for each pothole that impacts the budget.

As an example, please examine the chart below that compares two cold mix products: UPM® @ $100/ton and a competitor @ @ $85/ton. The initial saving is $30,000 dollars when going with the competitor’s product based on 2,000 tons per year and the difference in survivability rate between the two products of 45 points. (Survivability being the time material stays in the repair). However, the total impact to the budget is calculated at a $135,000 loss when using the competitor’s product due to increased labor, equipment and re=patching. When selecting a cold mix, the total cost of pothole repair is the preferred metric.

Laboratory Analysis

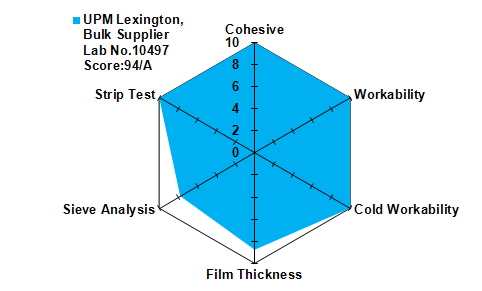

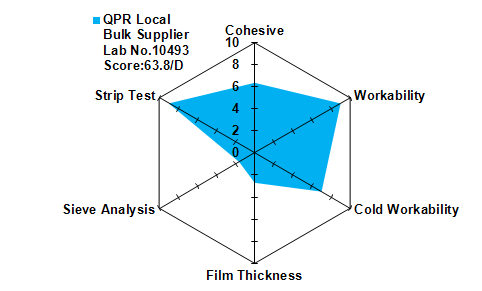

Comparing the cold mixes using performance parameters known to correlate with field performance scores, the QPR mix comes in at 63.8% or a “D”. Cold mixes scoring less than 80% will experience early failure. Parameters are weighted based on comparative field-lab correlation; creating a balanced rating, if achieved, will guarantee superior field performance. All parameters are interdependent; overall field performance deteriorates rapidly if any one parameter fails.

Cohesion & Adhesion

Measures the ability of the material to bond to itself and to the surrounding pavement. Performance related to the capability of the material to remain in place. Maintaining adequate adhesion and cohesion will determine the degree to which material ravels from the pothole.

Workability & Stability

Measures the force required to move and apply the material at greater than 72OF. Workability and stability must be balanced so that the material can be applied and yet stable enough to handle traffic loads. These are a function of gradation, viscosity, and application temperature.

Cold Workability

Measures the force required to move and apply the material in cold weather – less than 32OF.

Film Thickness

Measures the thickness of the asphalt surrounding the aggregate. Testing for the effective film takes into account aggregate gradation and absorption characteristics. Film thickness determines shelf life, cohesion, and workability.

Analysis

Cold mix is 95% aggregate. Proper gradation is critical to achieve proper compaction, workability and load-carrying strength. Surface characteristics, area, and absorption are critical for controlling stripping and workability.

Stripping

Measures the separation of asphalt from the aggregate. Performance relates to water-handling characteristics of material in wet environment (i.e. heavy rain).

Summary of Lexington’s Asphalt Pothole Repair Evaluation

The Lexington, Ky. program identified a superior-performing cold mix expected to provide significant annual saving to the city and drivers throughout Lexington. That product was UPM’s High Performance Cold Mix.

Those individuals participating in the program experienced first-hand the performance advantages working with a premium cold mix engineered to perform.

Incorporating local weather, road condition and local maintenance crews yielded results that are directly applicable to maintenance practices in the area.

The results from this evaluation provided the metrics needed to intelligently select UPM® as the highest value product for road repair in Lexington.

When considering candidate cold mix suppliers it’s important to note different business strategies. When selecting a cold mix product, it is reasonable to assume there will be questions, training and general support issues. The UPM® high performance cold mix is marketed as the leader in the industry by design and choice! Unique® Paving Materials Corporation has maintained their level of quality and consistency since 1959 and plans to continue with un-wavering commitment. Their QC program nearly guarantees each production of UPM® will match target performance. Unlike hot mix asphalt specifications which may be state-regulated and application-specific, design and performance specifications for cold mix do not exist. Without an effective QC program, performance variability will be highly variable.

It is recommended that those cities and towns interested in improving their overall maintenance strategy relative to pothole repair should design and implement a controlled performance evaluation with technically leading suppliers.

Product Pages

- Product Index

- Product Resource Guide

- Industry Studies & Related Articles

- Cold Mix FAQs

- Brochure & Instructions

- Cold Mix Asphalt Repair

- How to Repair a Pothole

- Product Comparison

Product Documents

- UPM® Cold Mix Asphalt Repair Brochure

- UPM® Cold Mix Data Sheet

- UPM® Permanent Pavement Patch Material Safety Data Sheet

- UPM® Cold Mix Liquid Blend – Ambient Safety Data Sheet

- UPM® Cold Mix Liquid Blend – Above Ambient Safety Data Sheet

- UPM® Cold Mix Bid Specifications

- UPM® Questions and Answers Sheet